What Is an Aluminum Curtain Wall System?

An aluminum curtain wall system is a non-load-bearing façade used to enclose buildings. Made from lightweight aluminum frames and glass or panel infills, it resists wind, water, and air infiltration while allowing natural light. It offers durability, design flexibility, and energy efficiency for modern architectural projects.

Why Choose Our Aluminum Curtain Wall System

Expertise in global project delivery

Comprehensive system and profile options

Precision manufacturing and quality assurance

Flexible custom design capabilities

Durable, corrosion-resistant materials

Fast lead times and reliable logistics

On-site installation support available

Energy-efficient, performance-tested systems

Modern aesthetics with versatile finishes

Responsive team for technical assistance

Need Aluminum Curtain Wall for Your Project?

System type

Profile Customization

Glazing Options

Shape And Size

Function And Performance

How We Test Aluminum Curtain Wall Performance?

To ensure durability and reliability, our aluminum curtain walls undergo rigorous testing, including air and water infiltration, structural wind load, seismic simulation, and thermal performance evaluations. These tests follow international standards to guarantee safety, energy efficiency, and long-term performance on real-world projects.

Aluminum Curtain Walls Applications

Aluminum curtain walls are widely favored across industries for their strength, flexibility, and modern appearance. Here’s where they are most commonly used:

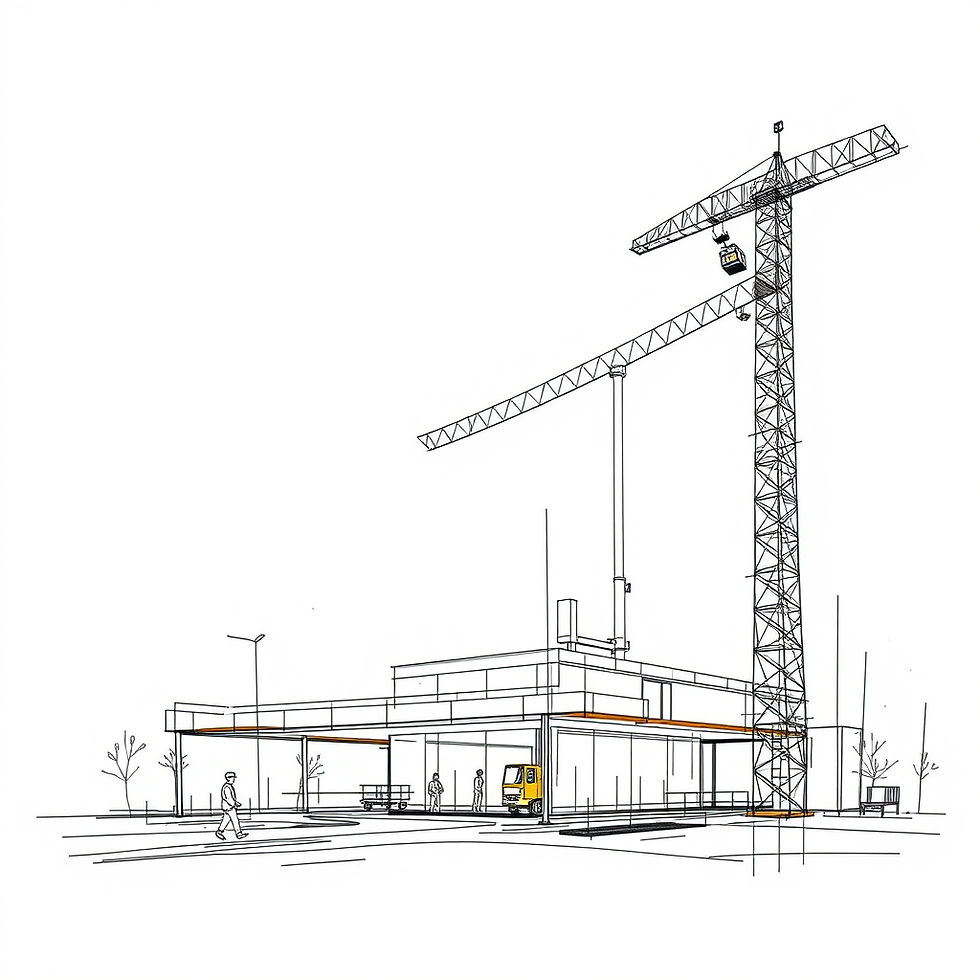

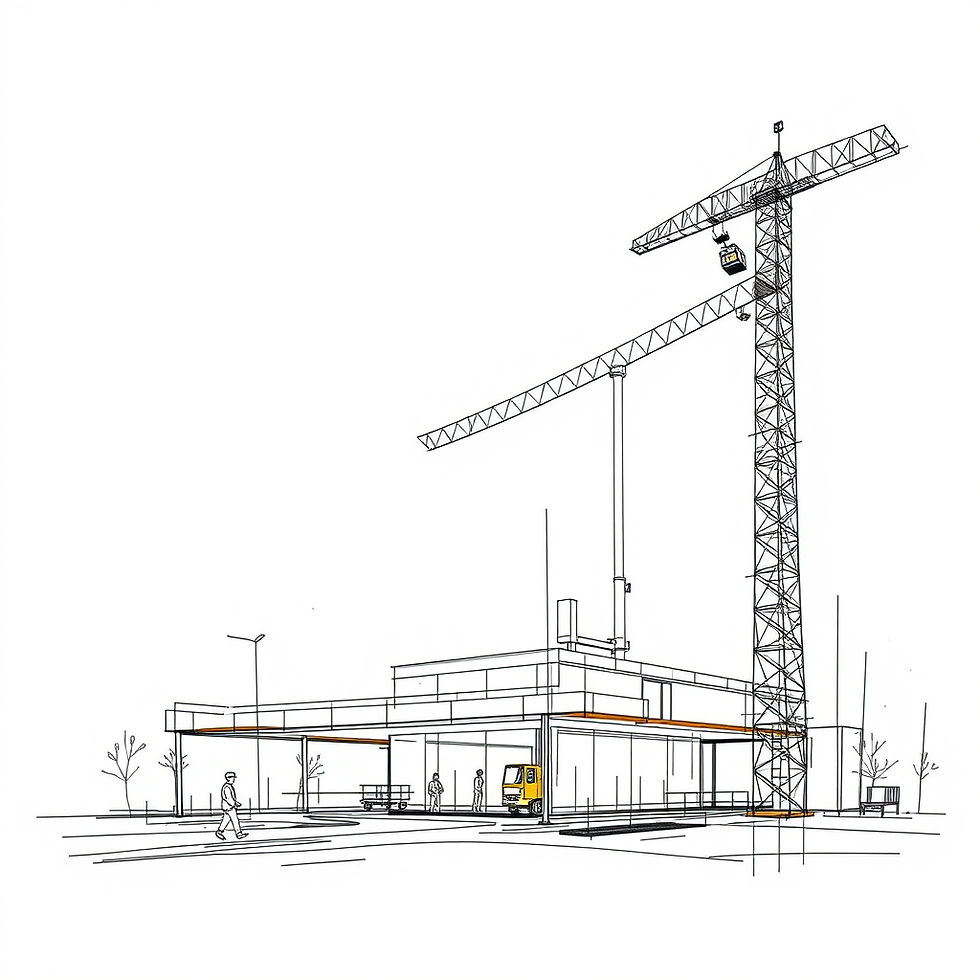

Aluminum Curtain Walls Gallery

Aluminum Curtain Wall Installation Support

On-site technical guidance provided

Detailed shop and system drawings

On-site technical guidance offered

Installer training sessions arranged

Remote troubleshooting and video support

Post-installation inspection assistance

Benefits of Aluminum Curtain Wall Systems

Lightweight structure reduces building load

High strength supports large glass spans

Excellent resistance to weather conditions

Corrosion-resistant in harsh environments

Enhances building thermal performance

Allows more natural daylight inside

Flexible for complex architectural designs

Easy maintenance and long lifespan

Modern and sleek exterior appearance

Supports green building certification efforts

Curtain Wall Maintenance Tips

Proper maintenance is essential to extend the lifespan and performance of your curtain wall system. Routine inspections and cleaning help prevent damage and ensure long-term durability.

-

Clean the Glass and Frames Regularly

-

Inspect Sealants and Gaskets

-

Check for Water Infiltration

-

Tighten and Secure Fasteners

-

Schedule Annual Professional Inspections

-

Keep Drainage Paths Clear

Aluminum vs. Steel Curtain Walls

Title | Aluminum Curtain Wall | Steel Curtain Wall |

|---|---|---|

Cost & Maintenance | Lower initial cost, low maintenance | Potentially higher cost; needs regular upkeep when coated |

Typical Applications | High-rise, commercial façades, residential | High-performance and heavy-glazed projects |

Design Flexibility | Excellent for curves, shapes, customization | Modern forming allows complex shapes |

Thermal Performance | Needs thermal breaks; good when insulated | Similar or better thermal control; less bridging |

Corrosion Resistance | Naturally corrosion-resistant | Requires galvanizing/coating to resist rust |

Wind Load Resistance | Handles moderate wind loads | Higher wind load capacity; less deflection |

Profile Size | Wider profiles needed due to lower stiffness | Narrower profiles allow cleaner sightlines

|

Weight & Strength | Lightweight, strong for standard spans | Three times stiffer; supports larger spans |

FAQs About Aluminum Curtain Wall

Aluminum is about 65% lighter and naturally corrosion-resistant, reducing structural load and maintenance. Steel offers greater stiffness (≈3× stronger), better supporting larger spans with slimmer profiles.

Yes—steel withstands higher loads, but aluminum systems, when properly engineered with reinforcements and anchorage, also meet global wind and seismic standards.

We use factory-quality gaskets, sealants, and drainage channels designed to pass ASTM E‑1105 and AAMA performance tests, ensuring tight weatherproofing.

No. Aluminum forms a natural oxide layer that resists rust. For coastal or harsh environments, optional anodized or powder-coated finishes offer added protection.

Profiles can be factory extruded or roll‑formed, sizes and shapes tailored, glass types selected, plus options like thermal breaks and integration with shading or smart glass.